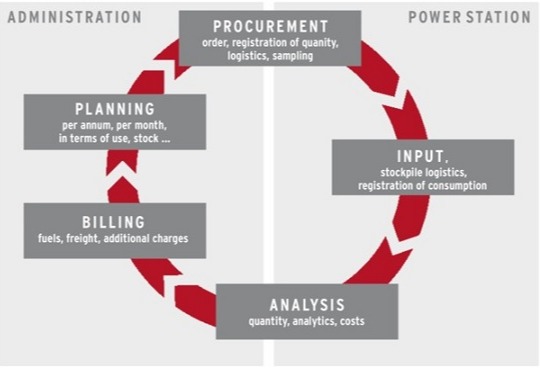

The system captures logistics and deliveries with detailed quality grades such as calorific value or sulphur content. MBS automatically highlights deviation from planning data and indicates missing cargoes. Data acquisition is automated to a large extent as interfaces allow MBS to be connected to logistics systems, belt weighers, weighbridges, silo sensors and analytical laboratories.