Optimization in mining

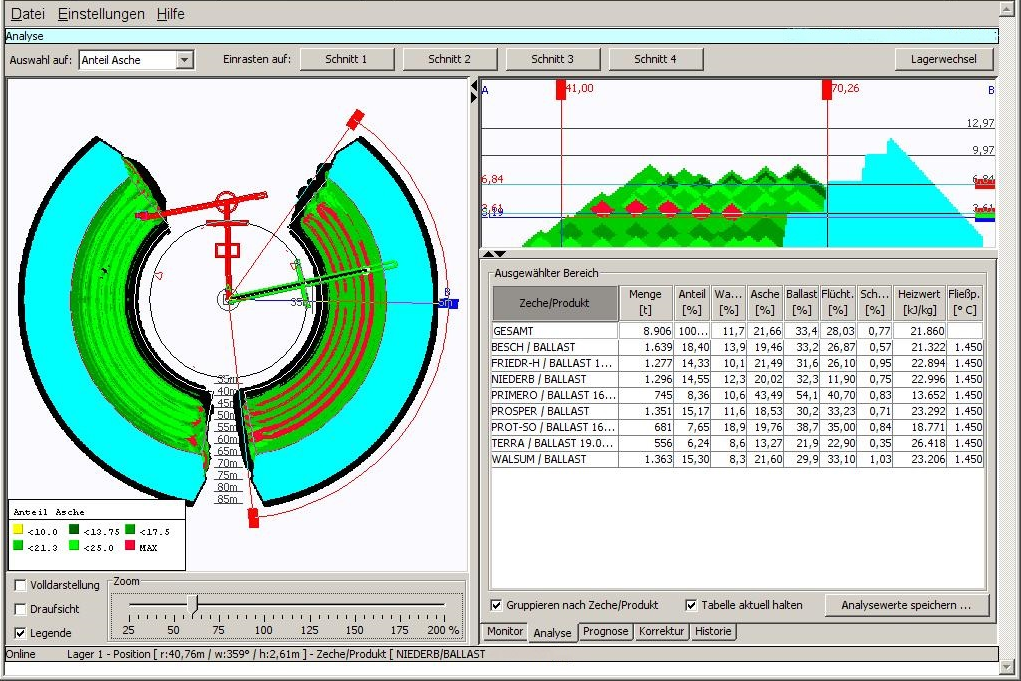

The MBS stockyard management system enables precise monitoring of stockpiling and dumping, a comprehensive overview of the stockpile composition and the monitoring of storage locations - all in real time. Due to the direct connection between the central elements of the stacker and reclaimer and the control technology, changes in quantities and qualities are charted in real time.

In MBS, the current position of the stacker can be seen digitally, as is the continuous display of the material quantities and qualities that have been removed. The MBS system simulates the material movements within the heap in order to be able to predict the final composition of the heap.

MBS transforms your stockpile from a black box into a precisely controlled tool. By entering orders directly for the control of the storage devices, you can manage the stockpile construction with one system from delivery planning to stacking by means of conveying devices. As a result, MBS Stockpile Management stands for an optimal material composition and an optimal production process.